01 02 03 04 05

Welded stainless ityhubhu ukwakhiwa

inkcazelo1

inkcazelo

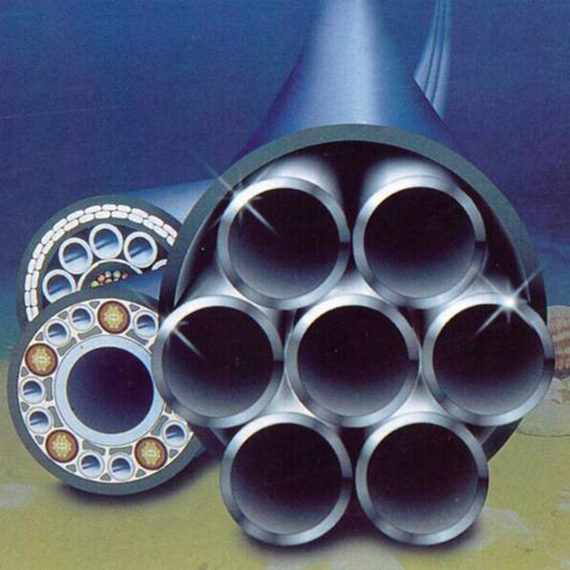

| Ukuchazwa kwemveliso | φ 12.7~4800mm 1.0~50 mm. |

| Ukusetyenziswa kwemveliso | Umbhobho wentsimbi yensimbi engenastainless isetyenziswa kakhulu kwipetroleum kunye nepetrochemical, i-oyile kunye negesi yendalo, ibhoyila yesikhululo samandla, ukuveliswa kwamandla, ukwakhiwa kweenqanawa kunye nezinye iindawo ezibalulekileyo; |

| Iimpawu zemveliso | Ukwakheka kweekhemikhali zemveliso, ukusebenza okuzinzileyo, yipetroleum yasekhaya kunye nepetrochemical, isikhululo samandla kwibhoyila amashishini atyunjelwe ukusebenzisa iimveliso; |

| Ukusebenza kwemveliso | Ukufakwa kwe-non-metallic, umxholo wegesi ophantsi, ukucoceka okuphezulu kwensimbi, iyunifomu kunye nokwakheka kweekhemikhali ezizinzile, kunye nokusebenza kakuhle kwenkonzo (ukumelana ne-corrosion, izakhiwo zomatshini, ukusebenza kokushisa okuphezulu), ukusebenza kokucubungula (ukusebenza okubandayo, ukusebenza kwe-thermal processing); |

| Iimveliso zemarike Dynamics | Ngokunyuka ngakumbi kotyalo-mali kummandla wophuhliso lwamandla, ugcino kunye nothutho, imfuno yombhobho odityanisiweyo wensimbi engenastainless nayo iya kwanda kakhulu, kwaye imakethi yensimbi engenasici inamandla amakhulu. |

Ukubunjwa kwezinto kunye namaBanga: Iityhubhu ezidityanisiweyo zensimbi ezingenasici zokwakhiwa ngokuqhelekileyo zenziwe ngamabakala ensimbi engenasici e-austenitic, njenge-304, 304L, 316, kunye ne-316L. La mabanga akhethwe ngenxa yokumelana nokugqwesa kwawo okugqwesileyo, ukomelela okuphezulu, kunye nokumila. Izinto ezixutywayo, ezibandakanya i-chromium kunye ne-nickel, zifake isandla ekwakhiweni komgangatho okhuselekileyo we-oxide ebusweni bentsimbi, ukwandisa ukuchasana kwayo nokubola kwiimeko ezahlukeneyo zokusingqongileyo.

Inkqubo yeWelding: Iityhubhu zenziwe ngenkqubo yokuwelda, ebandakanya ukudibanisa iziqwenga ezibini zentsimbi engenasici kusetyenziswa iindlela ezahlukeneyo zokuwelda. Iindlela zokudibanisa eziqhelekileyo kwiityhubhu zensimbi ezingenasici ziquka i-TIG (i-Tungsten Inert Gas) i-welding, i-MIG (i-Metal Inert Gas) i-welding, kunye ne-laser welding. Inkqubo ye-welding iqinisekisa ukudibanisa okuqinileyo kunye nokuhambelana phakathi kwamaphepha ensimbi, ukudala ityhubhu enokumelana nemithwalo yesakhiwo kunye noxinzelelo lwendalo.

Usetyenziso lwesakhiwo: Iityhubhu zetsimbi edityanisiweyo zisetyenziswa kakhulu ekwakhiweni kwezicelo zesakhiwo. Baqeshwe ekwenziweni kweekholomu, imiqadi, kunye neebrace, ukubonelela ngenkxaso ebalulekileyo kunye nokuzinza kwizakhiwo kunye neziseko. Iityhubhu zinegalelo kwintembeko yolwakhiwo ngokubanzi, ngakumbi kwizicelo apho ukuchasana nokubola kunye nezinto zokusingqongileyo kubalulekile.

Ukuxhathisa ukonakala: Enye yeenzuzo eziphambili zokusebenzisa iityhubhu zentsimbi edibeneyo edityanisiweyo kulwakhiwo luxhathiso olukhethekileyo lokutya. Oku kuxhathisa kubalulekile kwiiprojekthi zokwakha apho ukuba sesichengeni sokufuma, imichiza, kunye neemeko ezahlukeneyo zemozulu kunokukhokelela ekuwohlokeni kwemathiriyeli ngokuhamba kwexesha. Ukuxhatshazwa kwe-corrosion ye-stainless steel stainless iqinisekisa ixesha elide leetyhubhu kunye nokunciphisa iimfuno zokugcinwa, igalelo ekuzinzeni kweeprojekthi zokwakha.

Ukuguquguquka nokuguquguquka: Iityhubhu zentsimbi edityanisiweyo zifumaneka ngokobukhulu obahlukeneyo, iimilo, kunye nobukhulu, zibonelela ngezinto eziguquguqukayo kwizicelo zokwakha. Ziyakwazi ukulungelelaniswa ukuhlangabezana neemfuno ezithile zoyilo kwaye zilungelelanise iindlela ezahlukeneyo zokwakha. Oku bhetyebhetye kubenza balungele uluhlu olubanzi lweeprojekthi, kubandakanya izakhiwo zokuhlala, izakhiwo zorhwebo, kunye nophuhliso lweziseko ezingundoqo.

Isiphelo: Ukuqukumbela, iityhubhu ezidityanisiweyo zentsimbi engatyiwayo zolwakhiwo zidlala indima ebalulekileyo ekuboneleleni uzinzo lwesakhiwo, ukuxhathisa umhlwa, kunye nokuguquguquka kwiiprojekthi zokwakha. Ukusetyenziswa kwazo kunegalelo ekomeleleni kukonke kunye nobomi obude bezakhiwo, nto leyo ezenza zibe lolona khetho lukhethwayo ngabakhi bezakhiwo, iinjineli kunye nabakhi. Njengoko iteknoloji yokwakha ihambela phambili, indima yeetyhubhu zentsimbi edityanisiweyo engenakutyiwa kusenokwenzeka ukuba yande, inikezela ngezisombululo ezintsha kwiimfuno eziguqukayo zeshishini lokwakha.

01

Ekhaya

Ekhaya