01 02 03 04 05

ityhubhu engenamthungo yokutya kunye nokutya

inkcazelo1

inkcazelo

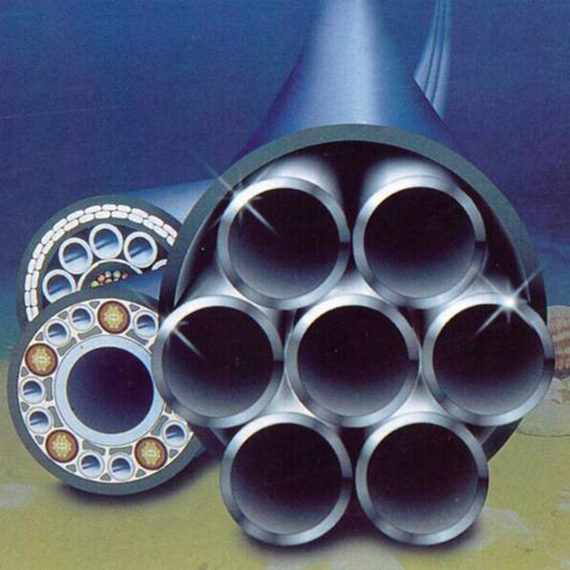

| Ukuchazwa kwemveliso | φ 6~7621.0~40 mm. |

| Ukusetyenziswa kwemveliso | Ipayipi yensimbi engenamthungo isetyenziswa kakhulu kwipetroleum kunye nepetrochemical, i-oyile kunye negesi yendalo, ibhoyila yesikhululo samandla, ukuveliswa kwamandla, ukwakhiwa kweenqanawa kunye nezinye iindawo ezibalulekileyo; |

| Iimpawu zemveliso | Ukwakheka kweekhemikhali zemveliso, ukusebenza okuzinzileyo, yipetroleum yasekhaya kunye nepetrochemical, isikhululo samandla kwibhoyila amashishini atyunjelwe ukusebenzisa iimveliso; |

| Ukusebenza kwemveliso | Ukufakwa kwe-non-metallic, umxholo wegesi ophantsi, ukucoceka okuphezulu kwensimbi, iyunifomu kunye nokwakheka kweekhemikhali ezizinzile, kunye nokusebenza kakuhle kwenkonzo (ukumelana ne-corrosion, izakhiwo zomatshini, ukusebenza kokushisa okuphezulu), ukusebenza kokucubungula (ukusebenza okubandayo, ukusebenza kwe-thermal processing); |

| Iimveliso zemarike Dynamics | I-TISCO I-50,000 yeetoni zeprojekthi yentsimbi engenamthungo yombhobho iya kuthatha indawo yokungenisa elizweni lombhobho wentsimbi engqindilili omkhulu wedayamitha enkulu. |

1. Izinto:

I-Stainless Steel: Ityhubhu yenziwe ngentsimbi engenanto, eyi-alloy enganyangekiyo kwaye ihlala ixesha elide. Amabakala aqhelekileyo ensimbi engenasici asetyenziselwa iibhubhu aquka i-304 (exhaphake kakhulu), i-316, i-321, kunye nabanye, nganye ineempawu ezithile ezifanelekileyo kwizicelo ezahlukeneyo.

2. Inkqubo yokuVelisa:

I-Welding: I-tube yenziwe ngenkqubo ye-welding, ebandakanya ukudibanisa iziqwenga ezimbini zensimbi engenasici usebenzisa ukushisa kunye noxinzelelo. Kukho iindlela ezahlukeneyo ze-welding eziqeshiweyo, ezifana ne-TIG (i-Tungsten Inert Gas) i-welding, i-MIG (i-Metal Inert Gas) i-welding, okanye ezinye iindlela, kuxhomekeke kwiinkcukacha kunye neemfuno.

3. Ubungakanani kunye nemilinganiselo:

I-Diameter: Iityhubhu ziza kwii-diameters ezahlukeneyo, ukusuka kwiisayizi ezincinci ezifanelekileyo kwizicelo ezichanekileyo ukuya kwiidayamitha ezinkulu zokusetyenziswa kwezoshishino.

Ubukhulu: Ubuninzi beendonga zetyhubhu bunokwahluka ngokusekelwe kusetyenziso olucetywayo. Iindonga ezityebileyo zinika amandla amakhulu kunye nokuqina.

4. Ukugqitywa komphezulu:

I-Polished okanye i-Unpolished: Ngokuxhomekeke kwisicelo, umphezulu wetyhubhu unokucolwa ukuze ufezekise ukugqiba okugudileyo, okukhazimulayo okanye ukushiywa kungakhange kuhlanjululwe kwiinjongo ezithile zoshishino okanye izakhiwo.

5. Isicelo:

I-Versatility: Iityhubhu ezidityanisiweyo ezingenasici zifumana izicelo kumashishini amaninzi, kubandakanywa ukwakhiwa, iimoto, i-petrochemical, ukutya kunye nesiselo, amayeza, kunye nokunye. Zisetyenziselwa ukuhambisa ulwelo, iigesi, okanye njengamalungu olwakhiwo.

6. UKuxhathisa kuMnyama:

IiPropati zeStainless Steel: Enye yeenzuzo eziphambili zokusebenzisa intsimbi engatyiwayo kukuxhathisa kwayo okugqwesileyo ekudlekeni, iyenze ilungele usetyenziso apho ukuvezwa kokufuma okanye izinto ezidlekayo ziyinkxalabo.

7. Imigangatho kunye neeNgcaciso:

Ukuthotyelwa: Ngokuxhomekeke kwisicelo kunye noshishino, iibhubhu ezingenasici ezidityanisiweyo zingadinga ukuhambelana nemigangatho ethile kunye neenkcukacha, ezifana nemigangatho ye-ASTM (i-American Society for Testing and Materials) okanye eminye imigangatho yamazwe ngamazwe.

8. Iindleko kunye nokufumaneka:

Iingqwalasela zoQoqosho: Iindleko zeetyhubhu ezingenasici ezidityanisiweyo zinokuhluka ngokusekelwe kwibakala lensimbi engenasici, ubungakanani kunye nezinye iinkcukacha. Ngokuqhelekileyo zifumaneka kubaboneleli kunye nabavelisi abakhethekileyo kwimveliso yensimbi engenasici.

Isishwankathelo, iityhubhu ezidityanisiweyo ziyakwazi ukusebenza ngokuguquguqukayo, zihlala ziqinile, kwaye ziyakwazi ukumelana ne-corrosion zisetyenziswa kumashishini ahlukeneyo ukuhambisa ulwelo, inkxaso yesakhiwo, kunye nezinye izicelo apho iipropathi zentsimbi engatyiwa ziluncedo.

Ukuqulunqwa kunye namaBanga eNtsimbi engatyiwa: Iityhubhu ezingenamthungo zenziwa ubukhulu becala ukusuka kwiintsimbi ze-austenitic ezingenasici, ezinezixa ezibalulekileyo zechromium kunye nenickel. Amanqanaba aqhelekileyo ensimbi engenasici asetyenziselwa ukuveliswa kweetyhubhu ezingenamthungo ziquka i-304, 304L, 316, kunye ne-316L. Ezi alloys zinika ukuxhathisa okugqwesileyo kwe-corrosion, nakwindawo ezingqongileyo ezirhabaxa, ngenxa yokwakheka kwe-passive oxide layer kumphezulu wentsimbi.

Inkqubo yokuVelisa engenamthungo: Inkqubo yokuvelisa ingenamthungo iyahlula le mibhobho ukusuka koogxa bawo abadityanisiweyo. Iityhubhu ezingenamthungo ziveliswa ngokugqobhoza ibhilithi okanye ibha eqinileyo ukwenza ityhubhu engenanto. Le nkqubo iqinisekisa isakhiwo esifanayo ngaphandle kobukho be-weld seams, okubangelwa ityhubhu enamandla aphuculweyo kunye nokuchasana noxinzelelo, ngokukodwa kwi-high-temperature kunye ne-high-pressure applications.

Usetyenziso: Iityhubhu ezingenamthungo ezingenamthungo zifumana ukusetyenziswa ngokubanzi kumashishini ahlukeneyo ngenxa yendibaniselwano eyodwa yokuxhathisa umhlwa, amandla, kunye nokuguquguquka. Kwicandelo le-oyile kunye negesi, le mibhobho isetyenziselwa ukuhambisa ulwelo kwimibhobho, apho ukuxhathisa kwizinto ezinobungozi kubalulekile. Kwishishini lokulungisa imichiza, iityhubhu ezingenamthungo ezingenazitya zisetyenziselwa ukuthutha iikhemikhali kunye nezinto ezibolayo.

Ishishini le-aerospace lixhomekeke kwezi ityhubhu kwizicelo ezifana ne-hydraulic systems kunye ne-structural components, apho umlinganiselo wamandla-to-weight ubalulekile. Ukongezelela, kumashishini okuvelisa amayeza kunye nokutya, iityhubhu ezingenasici zikhethwa kwiipropati zabo zokucoceka, okwenza ukuba zilungele ukuthutha ulwelo kunye neegesi ngaphandle komngcipheko wokungcola.

Ukuxhathisa ukonakala: Enye yeenzuzo eziphambili zeetyhubhu ezingenamthungo kukumelana kwazo nokugqwesa okungaqhelekanga. Isiqulatho sechromium kwintsimbi engatyiwayo senza umaleko weoksidi yokwenziwa ekhusela izinto kwizinto ezidlayo, kuquka iiasidi, iityuwa, kunye nokufuma. Oku kuxhathisa kwi-corrosion kuqinisekisa ubomi obude benkonzo kunye nokunciphisa iimfuno zokugcina.

Isiphelo: Ukuqukumbela, iityhubhu ezingenamthungo ezingenamthungo zibonisa incopho kubunjineli bezinto eziphathekayo, ezibonelela ngesisombululo esomeleleyo kunye ne-corrosion-resistant kwizicelo ezibalulekileyo. Inkqubo yabo yokuvelisa i-seamless, idibaniswe kunye neempawu zendalo zensimbi engenasici, ibenza babe ukhetho oluthembekileyo kumashishini afuna izinto eziphezulu zokusebenza. Njengoko itekhnoloji ihambela phambili, indima yeetyhubhu ezingenamthungo inokuthi yande, ibe negalelo kuphuhliso lweziseko zophuhliso ezisebenzayo nezizinzileyo kumacandelo awohlukeneyo.

01

Ekhaya

Ekhaya