01 02 03 04 05

Tšepe ea pinion e nepahetseng e phahameng

lintlha tsa sehlahisoa

| Brand | Letšoao la Amerika | Letšoao la Japane |

| 16MnCr(S)5,20MnCr(S)5,20MnCr5HH,20MnCSr5HH | ||

| SCM415(H), SCM420H, 20CrMo(H),31CrMoV9,42CrMoS4HH | 4118H, 4130H4140H, 4150H | SCM415H, SCM420HSCM822H,, SCM440H |

| 16CrMnBH,17CrMnBH,18CrMnBH | ||

| 17CrNiMo6, 18CrNiMo7-6, 340rNiMo6 | ||

| 20CrMnTiH, 20CrMnTiH1-H5 | ||

| 20CrH | SCr420H | |

| 20CrNiMoH, 22CrNiMoH, 27CrNiMoH | SAE8620H, 8622H8627H, 8620H | SNCM220H |

| 20CrMnMo | ||

| 19CrNi5 |

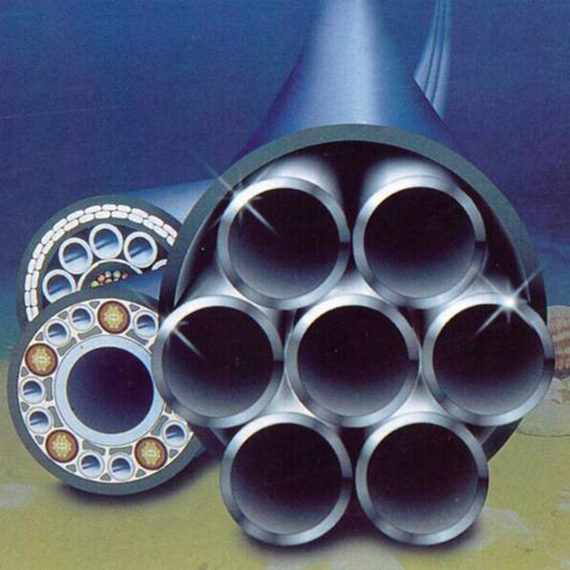

Sebopeho le Maemo: Pinion tšepe hangata ke tšepe ea boleng bo holimo ea alloy e khethang ka hloko lisebelisoa tsa alloy ho fihlela thepa e itseng ea mochini. Lintho tse tloaelehileng tsa alloying li kenyelletsa carbon, manganese, chromium, nickel le molybdenum. Sebopeho se nepahetseng se etselitsoe ho fana ka tekanyo ea boima, boima, le ho hanyetsa mokhathala, lintlha tsohle tsa bohlokoa bakeng sa maemo a boima ao likere le li-pinions li kopanang le tsona nakong ea ts'ebetso.

The microstructure ea pinion steel hangata e hloekisoa ka mekhoa ea phekolo ea mocheso joaloka ho tima le ho futhumatsa. Sena se ntlafatsa thepa ea eona ea mochini, ho netefatsa hore thepa e khona ho mamella khatello ea maikutlo, meroalo le likhohlano tse amanang le ts'ebetso ea gear.

Lisebelisoa: Pinion steel e fumana lits'ebetso ho pholletsa le liindasteri tse fapaneng moo lisebelisoa tsa lisebelisoa li leng bohlokoa ho ts'ebetso ea mochini. Boenjiniere ba likoloi, tšepe ea pinion e sebelisoa ha ho etsoa lisebelisoa tsa lisebelisoa bakeng sa phetisetso, litsamaiso tse fapaneng le mekhoa ea ho tsamaisa. Bokhoni ba eona ba ho mamella ho jara khafetsa, ho hanela ho roala, le ho boloka botsitso ba sebopeho ke ba bohlokoa bakeng sa bophelo bo bolelele le katleho ea likarolo tsena.

Mechineng ea indasteri, tšepe ea pinion e sebelisoa lits'ebetsong tsa lisebelisoa bakeng sa lisebelisoa tse kang li-conveyors, crane le mefuta e fapaneng ea mechini moo phetisetso ea motlakase e nepahetseng e leng bohlokoa. The lintho tse bonahalang durability le ho hanyetsa ho apara kenya letsoho hore ka kakaretso tšepahala le tlhahiso ea litsamaiso tsena.

Precision Engineering: Ho nepahala ho hlokehang litsamaisong tsa lisebelisoa, haholo lits'ebetsong tse kang liroboto le sepakapaka, ho hloka lisebelisoa tsa boleng bo holimo joalo ka tšepe ea pinion. Ho ts'oana le ho ts'oana ha thepa ho ea ka boima le lisebelisoa tsa mochini li bohlokoa bakeng sa ho netefatsa hore lisebelisoa li sebetsa hantle le tse tšepahalang.

Qetello: Qetellong, tšepe ea pinion e eme e le sesebelisoa se ikhethileng se etselitsoeng ho tobana le liphephetso tse ikhethang tse hlahisoang ke lisebelisoa tsa lisebelisoa le li-pinion. Sebopeho sa eona se entsoeng ka hloko le mekhoa ea phekolo ea mocheso e fella ka thepa e sebetsang ka mokhoa o tsitsitseng, ho hanyetsa le ho nepahala, e leng se etsang hore e be karolo ea bohlokoa ka ho fetisisa mochine o laolang liindasteri tse fapaneng. Ha theknoloji e ntse e hatela pele, karolo ea tšepe ea pinion e ntse e tsoela pele ho fetoha, e kenya letsoho ntlafatsong ea litsamaiso tse sebetsang hantle, tse tšepahalang le tse nepahetseng haholoanyane.

Lehae

Lehae